The application technology and advantages of monofilament in geotextile fabric

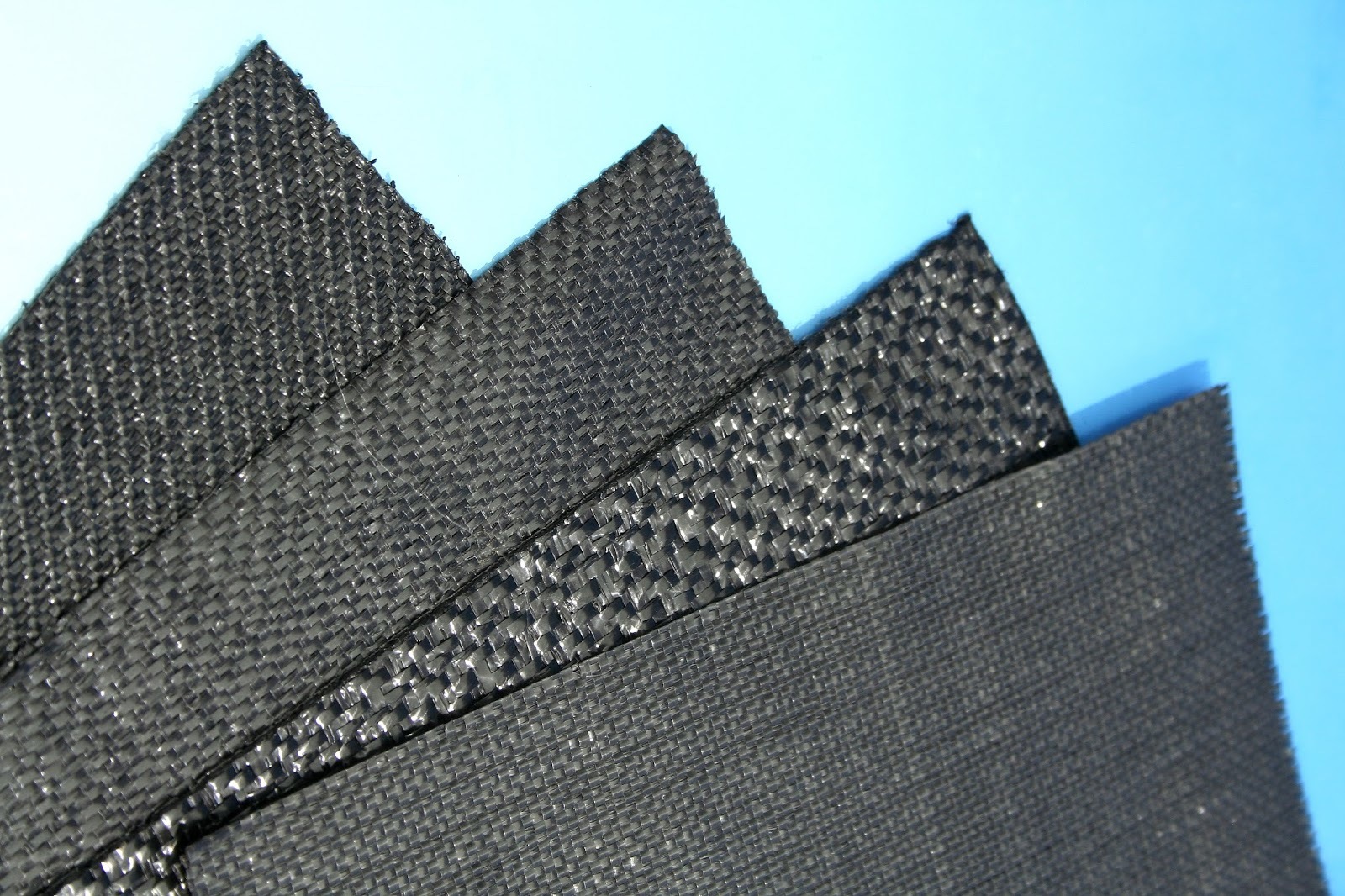

Monofilament yarn, as a synthetic fiber material with high strength and wear resistance, has been widely used in the field of geotextile base fabrics in recent years.

In road and railway engineering, monofilament geotextiles are often used for roadbed reinforcement and isolation. It can effectively disperse the load, prevent the settlement of the roadbed, and at the same time isolate soils of different properties to avoid strength loss caused by mixing. In water conservancy projects, monofilament geotextiles are used for embankment protection and drainage systems. Their high water permeability and filtration performance can prevent soil erosion and quickly drain accumulated water, ensuring the stability of the engineering structure.

In addition, monofilament geotextiles also play an important role in environmental engineering. For example, in landfill sites, it serves as an isolation layer to prevent harmful substances from seeping into groundwater. In sewage treatment plants, it is used for filtration and isolation to enhance treatment efficiency. The chemical resistance and durability of monofilaments enable them to maintain high efficiency even during long-term use.

Monofilament geotextile fabric is usually made of polyester (PET) or polypropylene (PP) monofilament fibers and has excellent mechanical properties, including high tensile strength, chemical corrosion resistance and UV resistance. This enables monofilament geotextile base fabric to maintain stable performance even in harsh environments. Whether it is road, water conservancy or environmental engineering, monofilament geotextiles can provide reliable solutions for the projects, helping to build safer and more sustainable infrastructure.

For more monofilament information, please follow NTEC Monofilament Technology Co., LTD.