NTEC's 160,000-ton/year Third Monofilament Intelligent Manufacturing Plant Topped Out, Ushering in a New Chapter of Intelligent Upgrade in the Monofilament Industry

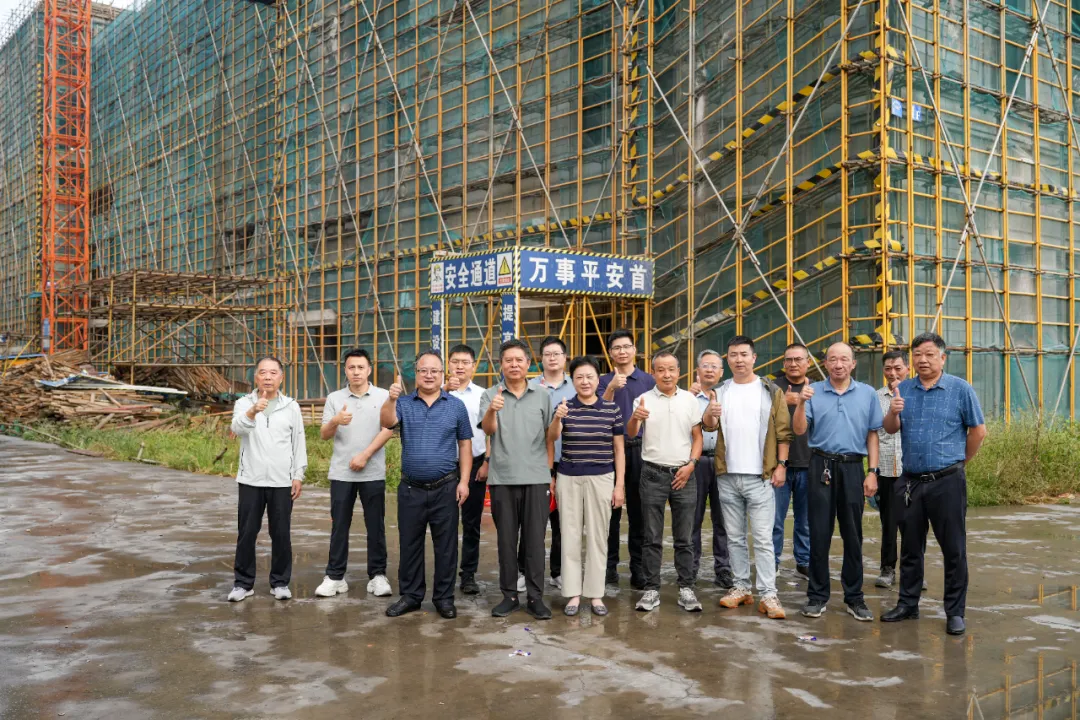

On September 18th, under the clear autumn sky and pleasant sunshine, the topping-out ceremony of the third monofilament intelligent manufacturing plant of Nantong NTEC Monofilament Technology Co., Ltd. (hereinafter referred to as "NTEC") was grandly held at the project construction site. Members of the company's management team, representatives of the construction party and relevant project leaders gathered together to witness this milestone moment. The site was decorated with fluttering colored flags and resounding applause, permeated with a warm and festive atmosphere.

As a key project for NTEC to layout the future development of the monofilament industry, the third monofilament intelligent manufacturing plant has attracted much attention from the industry since its launch. It is understood that the plant has a total planned production capacity of 160,000 tons and plans to put into operation 320 sets of advanced monofilament drawing machines, aiming to build a domestically leading and world-class intelligent monofilament production base. Compared with the company's existing production plants, the new plant has achieved an all-round leap in hardware configuration and technical level. With the core construction concept of "intelligent equipment, automated production and information-based management", it will not only greatly improve production efficiency and product quality, but also effectively reduce energy consumption, labor costs and material waste in the production process through the precise control of intelligent equipment, labor optimization of automated production lines and resource integration of information-based management, realizing a significant reduction in production costs. This injects the "triple powerful driving forces" of "efficiency, quality and cost" into the market competitiveness of the company's monofilament products.

At the topping-out ceremony, the general manager of NTEC delivered a speech. He said that the smooth topping-out of the third monofilament intelligent manufacturing plant is inseparable from the hard work and dedication of the construction team day and night, as well as the joint efforts and support of all employees of the company. The construction of this plant is an important measure for NTEC to respond to the national intelligent manufacturing development strategy and promote industrial transformation and upgrading, and it is also a key layout for the company to deepen its roots in the monofilament field and expand the global market. In the future, with the official commissioning of the new plant, 320 sets of drawing machines will fully release their production capacity. The annual production capacity of 160,000 tons will enable Xindike to achieve a qualitative leap in its supply capacity in the monofilament market; the intelligent production process can ensure a significant improvement in the stability of product quality, and the optimization of the production process can significantly shorten the delivery cycle. Moreover, the effective reduction in production costs will enable the company to provide more cost-effective products and services to global customers while ensuring product quality, truly fulfilling the development commitment of "serving global customers with higher quality, faster efficiency and better cost".

The representative of the construction party also spoke at the ceremony. He thanked NTEC for its trust and promised to continue to strictly control the project quality, accelerate the follow-up construction progress, ensure the project is completed and delivered on schedule, and build a high-quality and high-standard intelligent manufacturing plant for NTEC to help it realize the coordinated optimization of production capacity, quality and cost.

The topping-out of the third monofilament intelligent manufacturing plant marks that NTEC has taken a solid step on the road of large-scale, intelligent and low-cost development in the monofilament industry. In the future, relying on the new plant, NTEC will continue to increase investment in technological research and development, deepen the application of intelligent manufacturing, further consolidate and enhance its leading position in the monofilament industry. With the comprehensive advantages of "high production capacity, high quality and low cost", it will create greater value for global customers and make greater contributions to the innovative development of the monofilament industry.